Copper Electroplating

Copper electroplating is a process that involves depositing a layer of copper onto a metal substrate through an electrolyte solution containing copper ions. The process is carried out through the use of an electrical current, which causes the copper ions to be deposited onto the substrate.

Copper electroplating has a wide range of applications in various industries, including electronics, automotive, aerospace, and decorative items. It is an effective way to improve the surface properties of metal substrates, such as their corrosion resistance, wear resistance, and electrical conductivity.

Copper Electroplating Process

The copper electroplating process involves the following steps:

-

Cleaning: The metal substrate is thoroughly cleaned to remove any dirt, grease, or other contaminants that may interfere with the plating process.

-

Pre-treatment: The substrate is then subjected to a pre-treatment process, which involves the application of a layer of a special solution that prepares the surface for plating. This step is crucial to ensure good adhesion and uniform plating.

-

Electroplating: The substrate is immersed in an electrolyte solution containing copper ions and connected to a power source. An electrical current is passed through the solution, causing the copper ions to be deposited onto the substrate. The thickness of the copper layer can be controlled by adjusting the current density and plating time.

-

Post-treatment: After plating, the substrate is rinsed and subjected to a post-treatment process to remove any residual chemicals and improve the surface finish.

Types of Copper Electroplating

There are several types of copper electroplating, each with its own unique properties and applications:

-

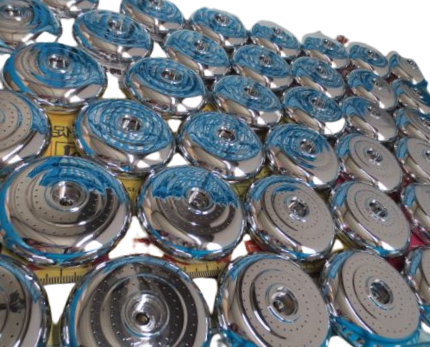

Acid copper plating: This type of plating is commonly used for decorative items, such as jewelry and bathroom fixtures. It produces a bright, shiny finish and can be easily polished.

-

Cyanide copper plating: This type of plating is used for applications where a thick layer of copper is required, such as electrical contacts and busbars. It is highly corrosive and requires special handling and disposal procedures.

-

Alkaline copper plating: This type of plating is commonly used in the electronics industry for printed circuit boards and semiconductor devices. It produces a fine-grained, uniform layer of copper with good adhesion.

Advantages and Disadvantages of Copper Electroplating

Copper electroplating offers several advantages, including:

-

Improved surface properties: Copper electroplating can improve the surface properties of metal substrates, such as their corrosion resistance, wear resistance, and electrical conductivity.

-

Cost-effective: Copper electroplating is a cost-effective way to improve the properties of metal substrates, compared to other coating methods, such as vacuum deposition and chemical vapor deposition.

-

Versatile: Copper electroplating can be used in a wide range of applications, including decorative items, automotive parts, and electronics.

However, copper electroplating also has some disadvantages, including:

-

Environmental concerns: The chemicals used in copper electroplating can be harmful to the environment if not handled and disposed of properly.

-

Limited thickness: Copper electroplating is limited in the thickness of the copper layer that can be deposited, making it unsuitable for applications requiring thick layers of copper.

-

Surface preparation: The quality of the copper layer depends on the quality of the surface preparation, which can be time-consuming and labor-intensive.

Conclusion

Copper electroplating is a versatile and cost-effective process that can improve the surface properties of metal substrates in various applications. It offers advantages such as improved corrosion resistance, wear resistance, and electrical conductivity. However, it also has some disadvantages, such as environmental concerns and limited thickness. Careful handling and disposal of the chemicals involved in the process are essential to ensure its safety and