Electroless Nickel Plating

Electroless nickel plating, also known as chemical or autocatalytic nickel plating, is a process of depositing a layer of nickel on a metal surface without the use of an electrical current. The process is a chemical reaction that involves the use of a special solution that contains nickel ions and other chemicals.

The electroless nickel plating process involves the immersion of the metal substrate to be plated into a solution of nickel salts, reducing agents, and stabilizers. The reducing agent, usually sodium hypophosphite, reacts with the nickel ions in the solution to deposit a layer of nickel on the surface of the substrate. This process is self-sustaining and continues until the desired thickness of nickel plating is achieved.

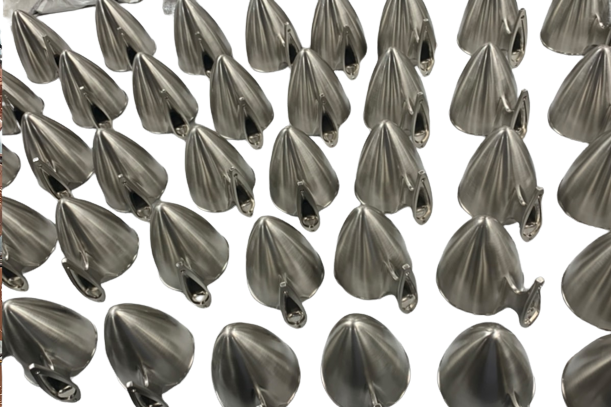

Electroless nickel plating provides several advantages over traditional electroplating methods. One of the main advantages is that the plating process is uniform and can be applied to complex shapes and surfaces. The process does not rely on an electrical current, which means that the plating will deposit evenly on all surfaces, regardless of shape or geometry.

Another advantage of electroless nickel plating is that it provides excellent wear and corrosion resistance. The plating is highly durable and provides a layer of protection against corrosion, making it ideal for use in harsh environments. The plating can also be heat-treated to further improve its wear and corrosion resistance properties.

Electroless nickel plating is widely used in various industries, including aerospace, automotive, and electronics. It is commonly used to provide wear and corrosion resistance to components such as engine parts, gears, bearings, and electronic connectors. The plating can also be used for decorative purposes, as it can be polished to a high shine.

Factors that can affect the quality of electroless nickel plating include the composition of the plating solution, the temperature of the solution, and the surface preparation of the substrate. Proper control of these factors is essential to ensure consistent, high-quality plating.

In conclusion, electroless nickel plating is a highly effective method of depositing a layer of nickel on a metal surface. It provides several advantages over traditional electroplating methods, including uniformity of deposition, excellent wear and corrosion resistance, and the ability to plate complex shapes and surfaces. With proper control of the plating process, electroless nickel plating can produce consistent, high-quality results.